Understanding Temperature and Humidity Control in Pharmaceutical Facilities: A Critical Factor in Product Quality

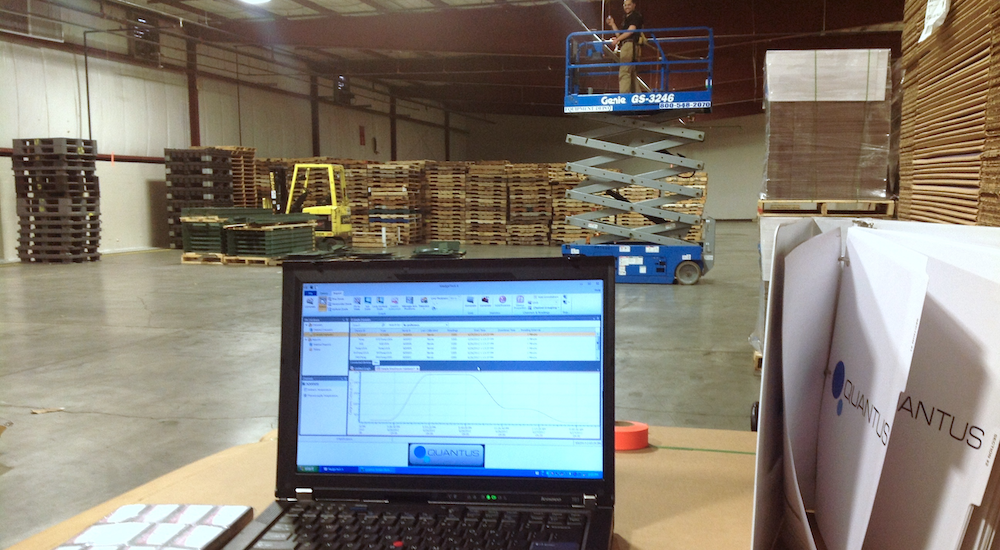

Temperature Mapping Validation is essential for controlled GMP storage in the Life Sciences industry. Precise temperature and humidity control ensures product quality, stability, and compliance.

Temperature and humidity control in pharmaceutical manufacturing facilities isn't just about comfort—it's a critical factor in ensuring product quality and regulatory compliance. A recent article in ISPE's Pharmaceutical Engineering journal highlights the complexities and importance of environmental control in pharmaceutical facilities.

Beyond Basic Compliance

Environmental control in pharmaceutical facilities serves multiple crucial purposes, from ensuring product quality to maintaining optimal equipment functionality. The challenge lies in balancing these requirements while maintaining energy efficiency and personnel comfort.

Strategic Approaches to Environmental Control

When designing environmental control systems, facilities must consider several key factors that impact both product quality and operational efficiency:

- Product-specific stability requirements

- Personnel comfort parameters

- Energy efficiency considerations

- Contamination risk mitigation

- Equipment operational requirements

The Role of Temperature Mapping

Temperature mapping validation is essential for ensuring environmental control systems perform as intended. This process involves comprehensive monitoring of temperature distribution throughout facilities, identification of potential hot spots or cold spots, and verification of system performance under various conditions.

Ensuring Compliance Through Expert Support

Professional validation services play a crucial role in helping facilities:

- Develop comprehensive environmental monitoring strategies

- Implement effective temperature mapping protocols

- Maintain documentation for regulatory compliance

- Optimize systems for both compliance and efficiency

Looking Ahead

As pharmaceutical manufacturing continues to evolve, maintaining precise environmental control becomes increasingly critical. Understanding and implementing proper temperature and humidity controls not only ensures regulatory compliance but also protects product quality and operational efficiency.

Ready to Optimize Your Environmental Controls?

Whether you need temperature mapping validation or comprehensive environmental monitoring solutions, we're here to help ensure your facility meets the highest quality standards.

Request Temperature Mapping Contact Our ExpertsThis article was inspired by "Temperature & Humidity Requirements in Pharmaceutical Facilities" from ISPE's Pharmaceutical Engineering journal (September-October 2021).

© 2025 Quantus, Inc. All Rights Reserved.

Company Headquarters: 3 Valley Square, Suite 120, Blue Bell, PA 19422

Phone: (866) 876-76537 | Email: service@goquantus.com

Read more

Determining Optimal Service Intervals in Life Sciences: A Comprehensive Guide

Co-Authored by: Technical Services Team Quantus, Inc. The leaders in life sciences are discovering that strategically optimized service intervals can unlock significant competitive advantages across their operations. When calibration schedules, equipment validation, and facility certifications are properly aligned with risk profiles and operational needs, these industry leaders typically see 15-25%

The Evolution of Decontamination Technology

Executive Summary In today's high-stakes Life Sciences environment, maintaining impeccable standards of cleanliness and safety is non-negotiable. Contamination can compromise research integrity, endanger personnel, and result in costly downtime. Quantus has established itself as an industry leader by implementing advanced chlorine dioxide (ClO₂) decontamination technology through a strategic

March 2025 Newsletter | Special Edition: Leadership Growth Announcement

Quantus Newsletter - Celebrating Growth & Leadership Building Our Future Together March 2025 Newsletter | Special Edition: Leadership Growth Announcement A Major Milestone in Our Journey Dear Valued Customers and Quantus Team Members, We are thrilled to announce a significant milestone in Quantus's evolution since our founding in 2012.

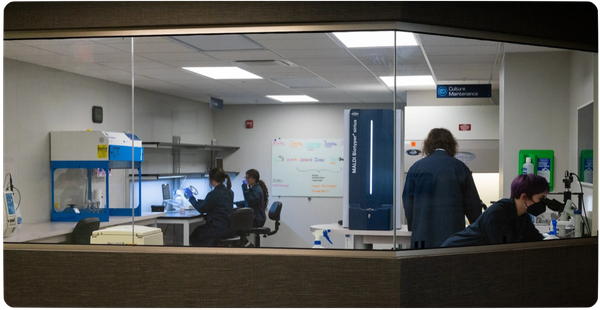

Unveiling New Microbiology Laboratory Services at Quantus

Discover Quantus’s new microbiology lab services—BIOSTORAGE, Growth Promotion, & Water Testing. Ideal for field teams, onsite labs, & business continuity. Learn more!