Understanding Glycol-Based Smoke Studies in Controlled Environments: A Technical Analysis

Glycol-based smoke studies help visualize airflow in controlled environments, ensuring compliance and contamination control. This article explores their applications in biotech and pharma, key testing considerations, and how Quantus enhances environmental monitoring for regulatory compliance.

Executive Summary

In the critical environment of Life Sciences facilities, the selection of appropriate visualization methods for airflow studies is paramount. This technical analysis examines why Quantus employs glycol-based smoke generators over traditional Water for Injection (WFI) systems, dry ice, and liquid nitrogen methods. Our analysis demonstrates that glycol-based systems provide superior particle simulation, enhanced control, and minimal environmental impact—crucial factors for maintaining the integrity of controlled environments.

Technical Comparison of Visualization Methods

1. Glycol vs. Water for Injection (WFI) Systems

While WFI systems are integral to pharmaceutical operations, their application in smoke studies presents several limitations compared to glycol-based systems:

- Particle Behavior Simulation: Glycol generates precisely controlled micron-sized droplets that accurately simulate airborne particulate behavior. WFI steam produces water vapor that fails to replicate actual contamination movement patterns.

- Environmental Impact: WFI steam can introduce unwanted moisture into controlled environments, potentially compromising sensitive equipment and surfaces. Glycol smoke dissipates with minimal residue.

- Visualization Accuracy: Glycol provides consistent, visible particles ideal for documenting airflow patterns. WFI steam's variable density and rapid dissipation can obscure critical airflow observations.

2. Advantages Over Alternative Methods

Comparative Analysis with CO₂ and N₂ Systems:

- Temperature Stability: Unlike dry ice (CO₂) or liquid nitrogen (N₂), glycol smoke maintains room temperature, preventing thermal disruption in controlled environments.

- Safety Profile: Glycol systems eliminate asphyxiation risks associated with CO₂ and N₂, while maintaining non-toxic operation when used according to protocol.

- Duration and Consistency: Glycol provides extended visualization periods with consistent density, superior to the rapid dissipation characteristics of alternative methods.

Implementation in Life Sciences Facilities

Quantus's selection of glycol-based systems aligns with critical requirements in Life Sciences applications:

- cGMP Compliance: Our glycol-based methodology supports current Good Manufacturing Practice requirements for environmental monitoring and control.

- Reproducible Results: Precise control over particle generation ensures consistent, documented results across multiple testing scenarios.

- Non-Interfering Operation: Minimal residue and neutral temperature characteristics preserve the integrity of controlled environments.

Conclusion

The implementation of glycol-based smoke studies represents a significant advancement in controlled environment testing methodology. This approach delivers superior visualization, enhanced safety, and minimal environmental impact—critical factors for Life Sciences facilities maintaining strict environmental controls. Quantus's adoption of this technology demonstrates our commitment to providing optimal solutions for controlled environment validation and monitoring.

Experience the Difference

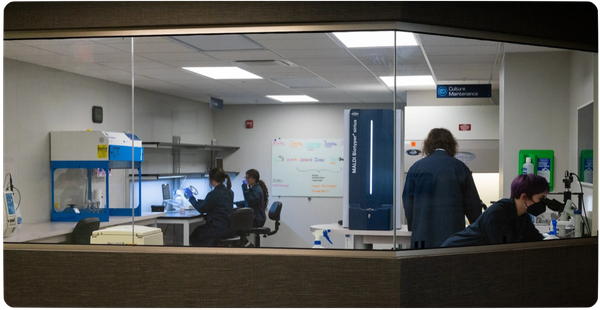

See our glycol-based smoke study methodology in action and discover how it can benefit your controlled environment testing needs.